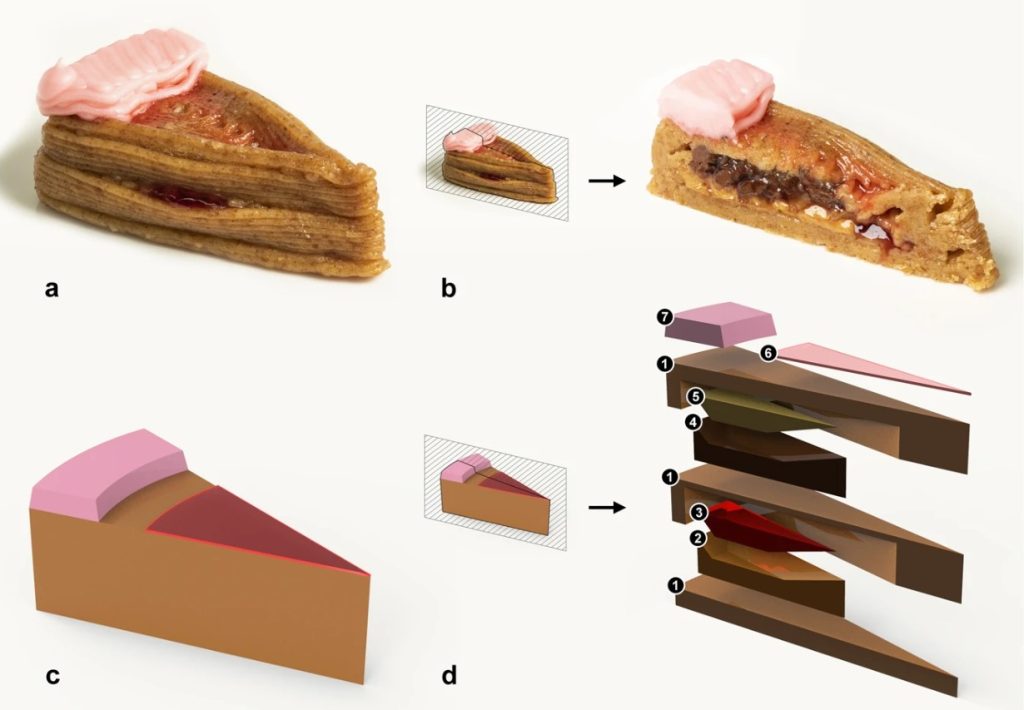

Researchers from Columbia University have used 3D printing to create a slice of cake using seven different ingredients. To achieve this, the team used a custom extrusion mechanism to pick and place the ingredients for 3D printing. Preparing the food included hand-mashing a banana with a fork to ensure the nozzle tip would not be obstructed during extrusion and preparing the Graham Cracker paste in a food processor.

The researchers used a blue laser diode operating at 445 nm to cook the food once it was printed, which they fixed to the moving printer head. They found the cooking apparatus could produce a power output of approximately 5–6 W. Using computer-aided design (CAD) software, the team modeled each material as a part file and combined them into an assembly before being exported for printing. Once fully modeled in CAD, parts were exported as an STL file, which allowed them to be processed by a slicer engine. The team then optimized the slicer engine for their custom 3D printer. Presumably, a further set of handheld “slicing engines” were then deployed to test the results by the hungry researchers.

The results show that flavors and textures can be localized on a millimeter scale to make new food experiences. The researchers made a slice of cake that looked like a typical one, but they controlled the extrusion path to make unique lattice structures and ingredient combinations that would be impossible to make with traditional extrusion or molding methods. However, the study also highlighted the challenges of using 3D printers to produce food, including the number of ingredients that can be used simultaneously and the difficulty of cooking the food once the ingredients are assembled.

3D printing food and digital cooking

Cooking in the digital age is transforming rapidly, and 3D food printing and laser cooking are among the latest technological developments. A recent academic paper suggests that these new ways of cooking offer options for making convenient, healthy, and cost-effective meals. This would make it easier for people to make their meals fit their tastes and nutritional needs. Even though grills, stoves, cooktops, and microwaves are still the most common ways to cook worldwide, “digital cooking” technologies may offer a more personalized way to prepare meals.

Food printing is a type of additive manufacturing that uses edible food inks to build 3D shapes from user-made models. On the other hand, laser cooking uses light with a lot of energy to heat things in a precise way. With these technologies, chefs can better control the amount of nutrients in meals, making them healthier and more personalized.

One of the biggest benefits of digital cooking technologies is that foods that don’t need as much human handling can reduce the chance of getting sick from food or spreading a disease. This is an essential benefit in the post-COVID-19 era. According to the academic paper, 3D printing of food is still in its early stages. Still, it could become more popular due to its customizability, convenience, and other benefits that suit the consumer. The paper also says that laser cooking is a great way to make food additives because it has a high resolution and can heat things deeply.

The innovation in the fields of 3D printing and laser cooking is not limited to food manufacturing. Many inventors and chefs are working on robots that make bread, salads, pizzas, plant-based meat 3D printers, machines that put together foods with more than one ingredient, pasta printers, automated cake decorators, personalized vitamin gummies, and other software-controlled heating appliances.

Even though software-integrated food-facing machines are moving away from manual control, they are also giving users more creative control by freeing up the mental energy that a human worker would normally use to move objects in the same way, with the same precision, repeatedly. Robotic systems that drop pastes, powders, and liquids in precise places based on a digital plan may be the way of the future when it comes to cooking.

The challenges to 3D printed food

As the benefits of digital cooking technologies continue to expand, might 3D printers and laser cooking become staple home and industrial cooking devices?

Even though 3D food printing is becoming increasingly popular, some might say that it doesn’t fit what consumers want now, which is whole foods and “naturalness” in food products. Processed foods, which often include highly processed or “ultra-processed” foods, have been linked to the overweight and obesity crisis, which costs the US $50 billion a year in lost worker productivity and health care costs.

But people who like the idea of 3D printing food say that it can help the environment, make it easier to get ingredients close to home, and let people make food that fits their tastes and nutritional needs. 3D food printing can also help people who have trouble swallowing or digesting. It can also make food look more appealing and allow large-scale production in a factory or food service kitchen.

Moreover, the technology offers manufacturers opportunities to extend shelf-life and reduce food waste, as users would only print the ingredients they want to consume. Although 3D food printing is still in its early stages, it has the potential to fill a market gap for food of different sizes, shapes, and textures.

As the technology improves, people who support it hope it will become easier and faster for consumers to use, leading to more home cooking and better health. The growing interest in 3D food printing is shown by the fact that the size of the market is expected to reach $425 billion by 2025.

The future of software-controlled cooking was authored by Jonathan David Blutinger, Christen Cupples Cooper, Shravan Karthik, Alissa Tsai, Noà Samarelli, Erika Storvick, Gabriel Seymour, Elise Liu, Yorán Meijers & Hod Lipson and is published in the journal npj Science of Food.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays. Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.