Courtesy of its world-leading solar and wind resources, and access to the platinum group metals (PGMs) used in PEM electrolysers needed to produce green hydrogen and in fuel cells to generate electricity from hydrogen, South Africa is now primed to capitalize both in terms of hydrogen generation and consumption.

Consortia-led feasibility study identifies three key hydrogen valley hubs

In collaboration with South Africa’s Department of Science and Innovation (DSI), the South African National Development Institute (SANEDI), fellow Hydrogen Council steering member ENGIE, and Bambili Energy, Anglo American completed a hydrogen valley feasibility study in October 2021. Please click here to access the full report.

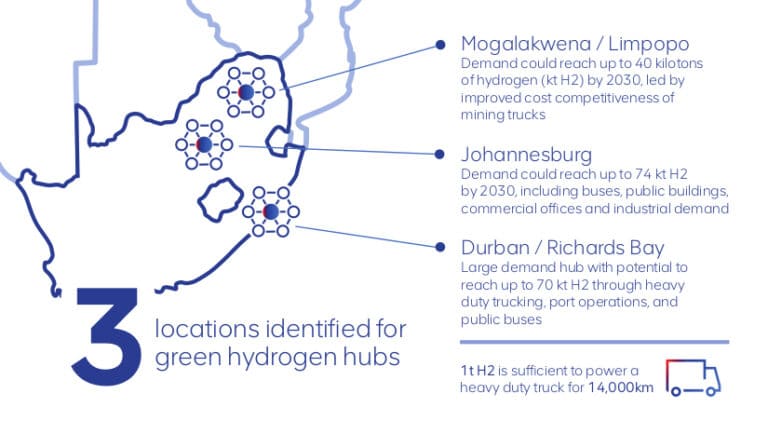

The feasibility study identifies three hubs – Johannesburg, extending to Rustenburg and Pretoria; Durban, encompassing the city itself and Richards Bay; and Limpopo province centred around Anglo American’s Mogalakwena PGMs mine – with a fundamental role to play in integrating hydrogen into South Africa’s economy, and in establishing South Africa and its abundant renewable energy resources as a strategically important centre for green hydrogen production.

Hydrogen valley presents substantial economic and employment potential

The results of the independently conducted feasibility study show that the hydrogen valley could add between USD$4-9 billion to South African GDP (direct and indirect contributions) by 2050, while also creating between 14,000 – 30,000 direct and indirect jobs per year. These jobs will span the entire hydrogen value chain, from research and development, engineering and maintenance, to training and outreach – across sourcing, production, transportation, storage and applications such as fuel cell manufacturing.

Nine individual pilot projects have been identified across these hubs and are recommended to be prioritised by developers. They span the transport, industrial, and construction sectors.

Since the publication of the feasibility study results, Anglo American has worked with South Africa’s DSI and other partners such as Bambili Energy and ENGIE on the implementation of relevant projects, all the while continuing to advance independent efforts to introduce hydrogen powered solutions to its mines as part of the company’s targets to achieve carbon neutrality across its operations by 2040.

The investment in renewable hydrogen production technology at its Mogalakwena PGMs mine, and in the development of hydrogen-powered fuel cell mine haul trucks – the world’s largest to run on hydrogen – is a prime example of this approach.

nuGenTM – Anglo American's Zero Emissions Haulage Solution

nuGenTM represents a different way of thinking about mining. Anglo American’s FutureSmart MiningTM programme is developing and implementing step-change innovations that are transforming the very nature of mining and how stakeholders experience and interact with the industry. Anglo American is now working towards a world where mines are integrated, automated, carbon neutral, and use far less water.

This broader objective is the inspiration behind the nuGenTM Zero Emission Haulage Solution (ZEHS) project, an end-to-end integrated green hydrogen production, fuelling, and haulage system for mine sites.

The world’s lightest 510 tonne truck

The pilot for the nuGenTM Zero Emission Haulage Solution is a hydrogen-powered ultra-class mine haul truck. It’s an ambitious project that marks the first time a truck of this size and load capacity (a 220 tonne truck with a load capacity of 290 tonne = a total laden weight of 510 tonne) has been converted to run on hydrogen that will be produced on-site in hybrid combination with a battery.

- The nuGenTM truck is retrofitted from a diesel-powered vehicle. The truck uses a hybrid hydrogen fuel cell providing roughly half of the power and a battery pack the other half, to allow energy recovery from braking.

- Hydrogen enters the fuel cell from the tank and mixes with oxygen to create water in a chemical reaction catalysed by platinum. This generates electricity that is used to power the motors that drive the wheels. The only emission from the vehicle is water vapour.

- The 2-megawatt hybrid battery/hydrogen fuel cell powerplant, which replaces the diesel engine installed, has been designed by Anglo American and its partner First Mode in Seattle, USA.

- The power management and battery systems in the truck have been developed to improve overall efficiency by recovering energy when the haul trucks travel downhill, through regenerative braking.

- By harvesting the regenerative energy created when driving downhill, we reduce our need for external energy. This energy, stored in the battery, together with the hydrogen extends the truck’s range and reduces the out of cycle time for the trucks, since hydrogen refuelling is significantly faster than recharging batteries.

As part of the integrated nuGenTM solution, Anglo American has also built a zero emission vehicles hydrogen production, storage, and refuelling complex at Mogalakwena that incorporates the largest electrolyser in Africa and a solar PV field to support the operation of the haul truck. Hydrogen Council steering member ENGIE is the hydrogen producer and supplier in this proof-of-concept project.

Looking to the future

Anglo American now plans to retrofit 40 diesel powered ultra-class haul trucks at Mogalakwena to hydrogen, and then roll this technology out across their global fleet of around 400 trucks. The launch of the nuGenTM truck provides a real-world case for the wider adoption and use of hydrogen across the heaviest duty forms of transport.

With haul trucks representing up to 80% of diesel emissions at Anglo American’s sites, this technology will make a major contribution towards the company’s operational carbon neutrality target. The truck is a tangible and relatable example of what can be achieved by having a clear vision for what may be possible with hydrogen, and then partnering with others to deliver a breakthrough outcome.