A group of researchers from China and the U.S. have used 3D printing to create 1:1 scale pelvic models of hip fracture patients, to aid in the surgical treatment of both-column acetabular fractures.

In the study, the researchers compare traditional methods of contouring plates intra-operatively with the use of pre-contoured plates according to physical 3D printed pelvic models. The paper presents the use of both 3D printing and virtual simulation in pre-operative planning for both-column acetabular fractures.

Ultimately, the researchers hypothesize that 3D printing can assist orthopedic surgeons in shortening the time and improving the clinical outcomes of the surgical procedure.

The benefits of 3D printing in surgical procedures

An acetabular fracture is a break in the socket portion of the “ball-and-socket” hip joint. Both-column acetabular fractures refer to when the entire weight-bearing articular surface is detached from the sacroiliac joint. They are the most serious and the second most common type of acetabular fractures, the researchers explain. According to the paper, “approximately 21 percent of all acetabular fractures involving both columns of the acetabulum require good reduction and stable internal fixation to prevent post-traumatic arthritis and obtain excellent clinical outcomes.”

However, surgical treatment of both-column acetabular fractures have proved challenging because of the complex acetabular fracture patterns and curved surface of the acetabulum. Traditional operations for acetabular fractures are limited to a small number of anterior approaches, and require contouring of the plates mid-surgery, which increases the operation time as well as blood loss.

The researchers identify 3D printing technology as a potential route for helping surgeons understand the shape of the fracture fragments and simulate the reduction of the fracture, especially in complex acetabular fractures. “Three-dimensional (3D) printing technology is developing rapidly and is broadly used in clinical applications because it is easily accessible in terms of the equipment and cost,” the authors add.

3D printing can help surgical procedures for both-column acetabular fractures via pre-operative virtual simulations with 3D printed, 1:1 scaled pelvic models for pre-contouring of the plates. Explaining the benefits and limitations of this process, the researchers state that “Prior studies have revealed that the application of 3D printing technology in the surgical treatment of acetabular fractures can significantly reduce the operation time and blood loss but cannot obtain a fracture reduction of significantly better quality.”

The researchers believe that, with 3D printing technology, orthopedic surgeons will be able to shorten operation time while improving the clinical outcomes, such as the post-operative fracture reduction quality, hip joint function, and complication rate.

Indeed, 3D printing has previously seen successful applications in various types of hip surgeries. In late 2019, LOGEEKs Medical Systems (MS), revealed that its 3D printed implants had been used in a reconstructive restoration surgery of the hip joint, in conjunction with impaction bone grafting. In the year prior to that, Florida surgeons also performed a hip replacement surgery using 3D printed implants from ConforMIS, a medical technology company based in Massachusetts.

3D printing more effective in treating hip fractures

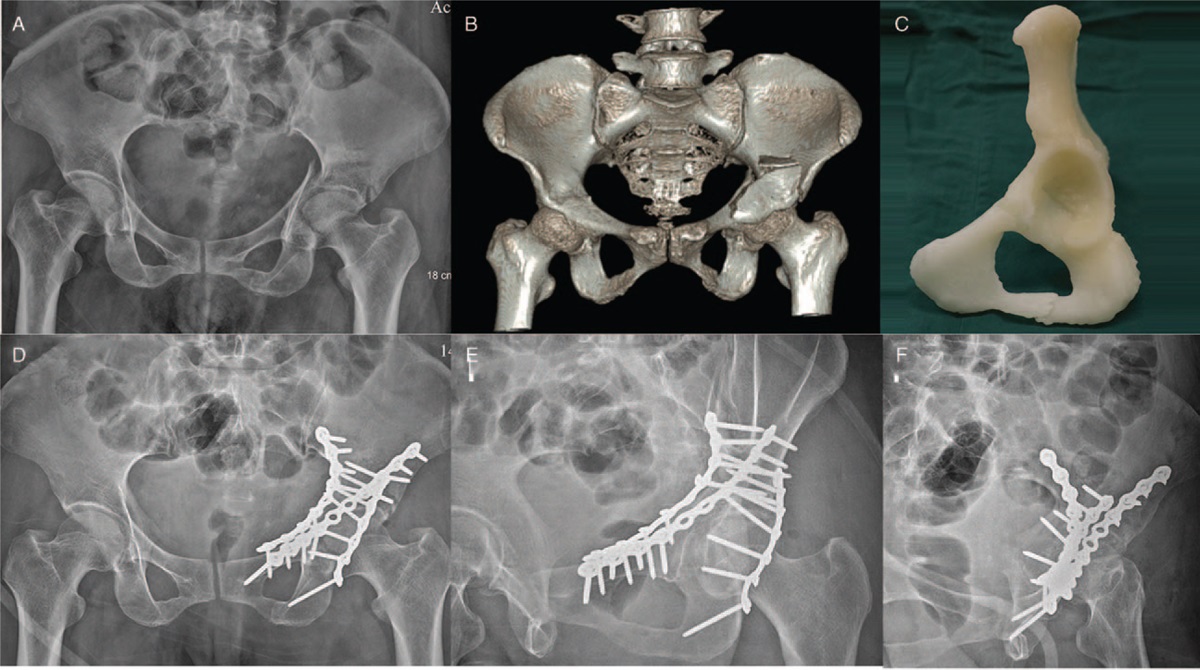

To carry out their research, the team established a randomized prospective case–control study of 40 patients diagnosed with both-column acetabular fractures between September 2013 and September 2017. Twenty patients were allocated to the 3D printing group, and the other 20 patients were allocated to the conventional method group using block randomization.

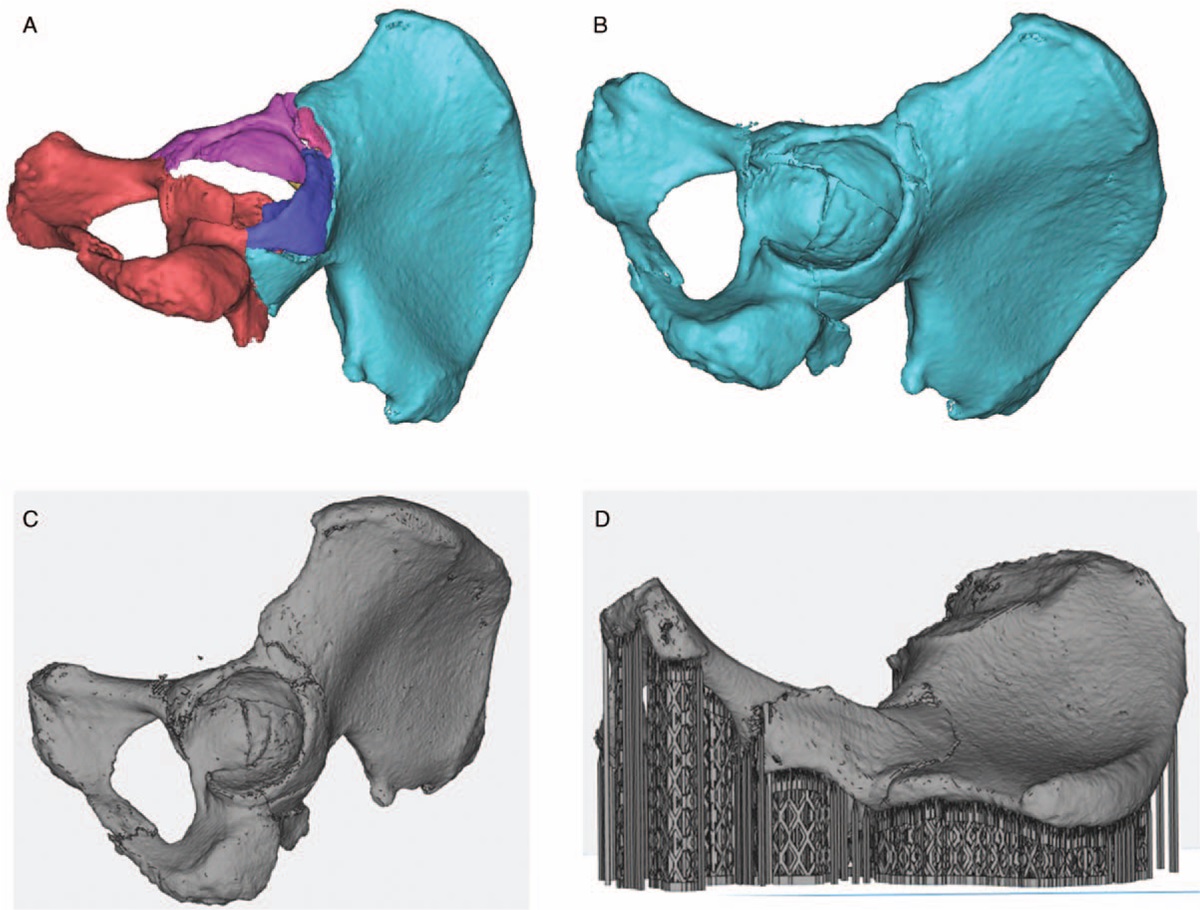

The method for virtual simulation and 3D printing models of fracture fragments involved saving topography images of each patient’s pelvis as Digital Imaging and Communication in Medicine (DICOM) files. These were then imported into MIMICS, the medical 3D image processing software developed by Materialise. The fracture fragments were reduced anatomically using the reposition function, and then exported as STL files and imported into Materialise Magics software for fixing and support generation.

The final STL was then 3D printed and used to pre-contour the plates for surgical procedure, with the length of the screws measured using the 3D printed reduced hemi-pelvis model. After the surgical simulation, the pre-contoured anatomic plates and screws were disinfected and used to aid the acetabular surgical procedures.

From evaluating the results, the researchers observed virtual simulation and 3D printing as a more effective method than conventional techniques for treating both-column acetabular fractures: “We found that the post-operative fracture reduction quality and the hip joint function in the 3D printing group were significantly better than those in the conventional method group […] The 3D printed reduced hemi-pelvis models may help in anatomically pre-contouring the plates to obtain good fracture reduction quality and hip joint function and reduce the risk of traumatic arthritis […] The operation time, the instrumentation time, and the time of intra-operative fluoroscopy were significantly shorter, and the blood loss and blood transfusion were significantly less in the 3D printing group than in the conventional method group.”

The paper, “Surgical treatment for both-column acetabular fractures using pre-operative virtual simulation and three-dimensional printing techniques,” is published in Chinese Medical Journal. It is written by Huang JH, Liao H, Tan XY, Xing WR, Zhou Q, Zheng YS, Cao HY and Zeng CJ.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D models of the fracture fragments. Image via Chinese Medical Journal.