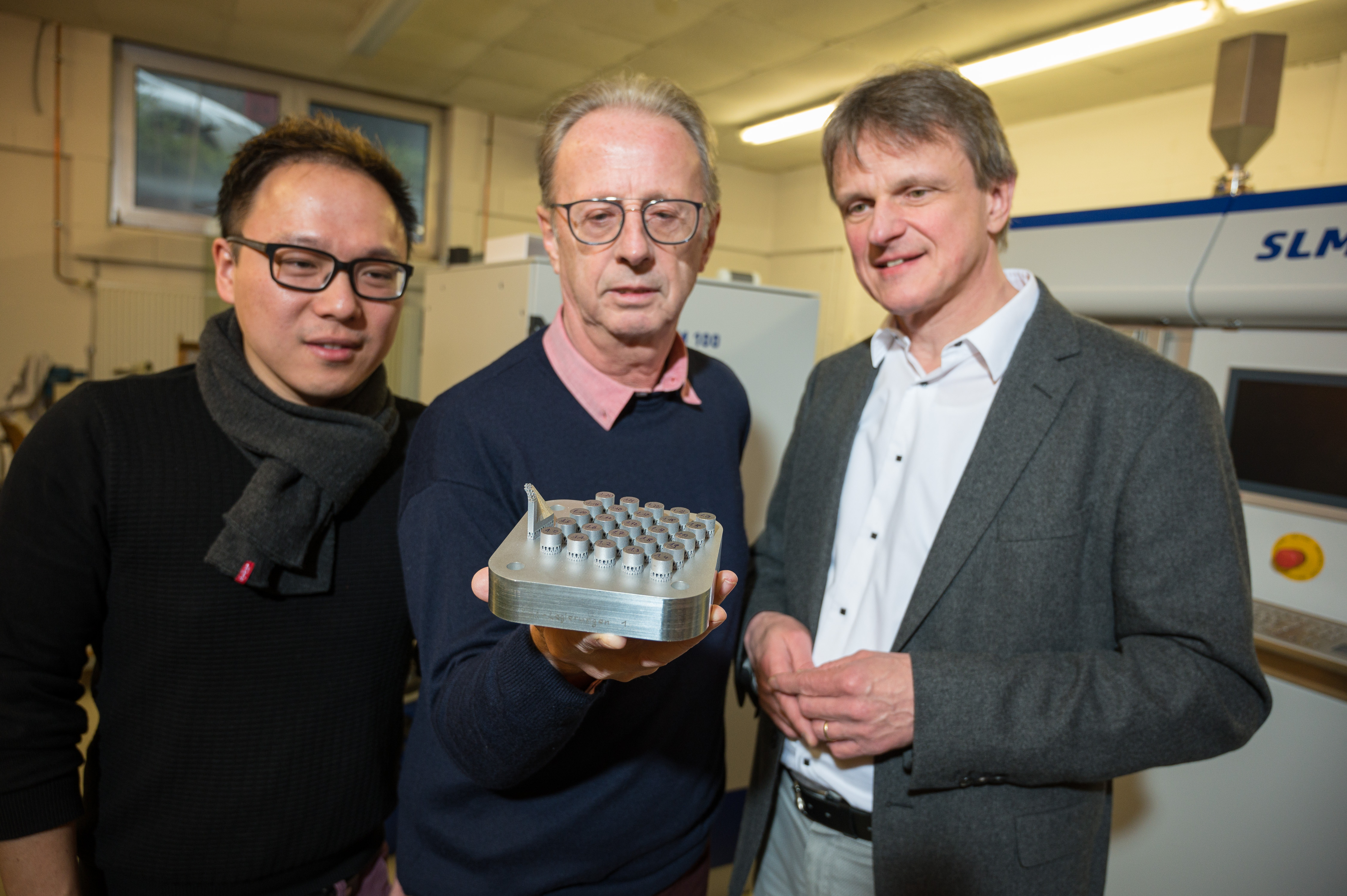

Researchers at Saarland University have developed a non-contact method for transforming 3D printed metal parts into high-precision technical components for specialist applications.

The novel technique leverages electrochemical machining (ECM) to post-process additive manufactured metal components into precision-finished parts with complex geometries and dimensional tolerances of a few thousandths of a millimetre.

Such a method is intended to improve the implementation of 3D printed metal parts in applications that have to meet extremely strict dimensional requirements in industries such as automotive and aerospace.

“Our technology for post-processing additively manufactured metal parts offers a cost-effective means of producing high-precision functional surfaces for applications where extremely tight tolerances are crucial,” explains Professor Dirk Bähre from Saarland University.

“It enables large numbers of parts to be post-processed efficiently and economically.”

Meeting the dimensional requirements for specialized applications

Complex technical systems like the engines that power cars, planes or rockets are made from a large number of highly specialized metal components. Often, to ensure that these parts fit together perfectly and are able to weather extreme mechanical stresses, each of them has to be manufactured very precisely. “Tolerances can be down in the micrometre range,” explains Professor Bähre, who developed the new post-processing method with his research team at Saarland University.

Metal 3D printing is already an established means of fabricating components with complex geometries, from engine parts to anatomical models. However, the researchers state that often 3D printing, which builds parts up layer by layer, does not meet extremely strict dimensional requirements in many specialized applications. And in some cases, the geometry of the part may be too complex to be produced by conventional metal 3D printing.

As such, Professor Bähre and his team set themselves the goal of refining 3D printed metal parts so that their dimensions were correct down to a few thousandths of a millimetre. Specialists in the field of precision machining and finishing, the research team has developed novel techniques in which they combine metal 3D printing with ECM, a method of removing metal by an electrochemical process. By removing material electrochemically, even the most complex geometries can be created in the hardest of metals. ‘Our non-destructive, non-contact manufacturing technology enables us to efficiently machine parts with intricate geometries even when made from high-strength materials,’ explains Bähre.

Various steps have been taken to advance the post-processing of metal parts produced by additive manufacturing by different companies. In 2019, Vermont-based metal additive manufacturing company A3DM Technologies, and Spanish advanced technology firm GPA Innova announced a collaboration to develop optimized processing parameters for GPA Innova’s “DryLyte” dry electro-polishing process for metal alloys used in powder based additive manufacturing.

Furthermore, the UK’s Manufacturing Technology Centre (MTC), located in Coventry, unveiled the results of its FlexiFinish project in July 2018. The project sought to address the poor surface finish quality of metal parts produced through additive manufacturing, by providing its own automated additive manufacturing post-processing solution for metallic components.

Post-processing 3D printed metal with electrochemical machining

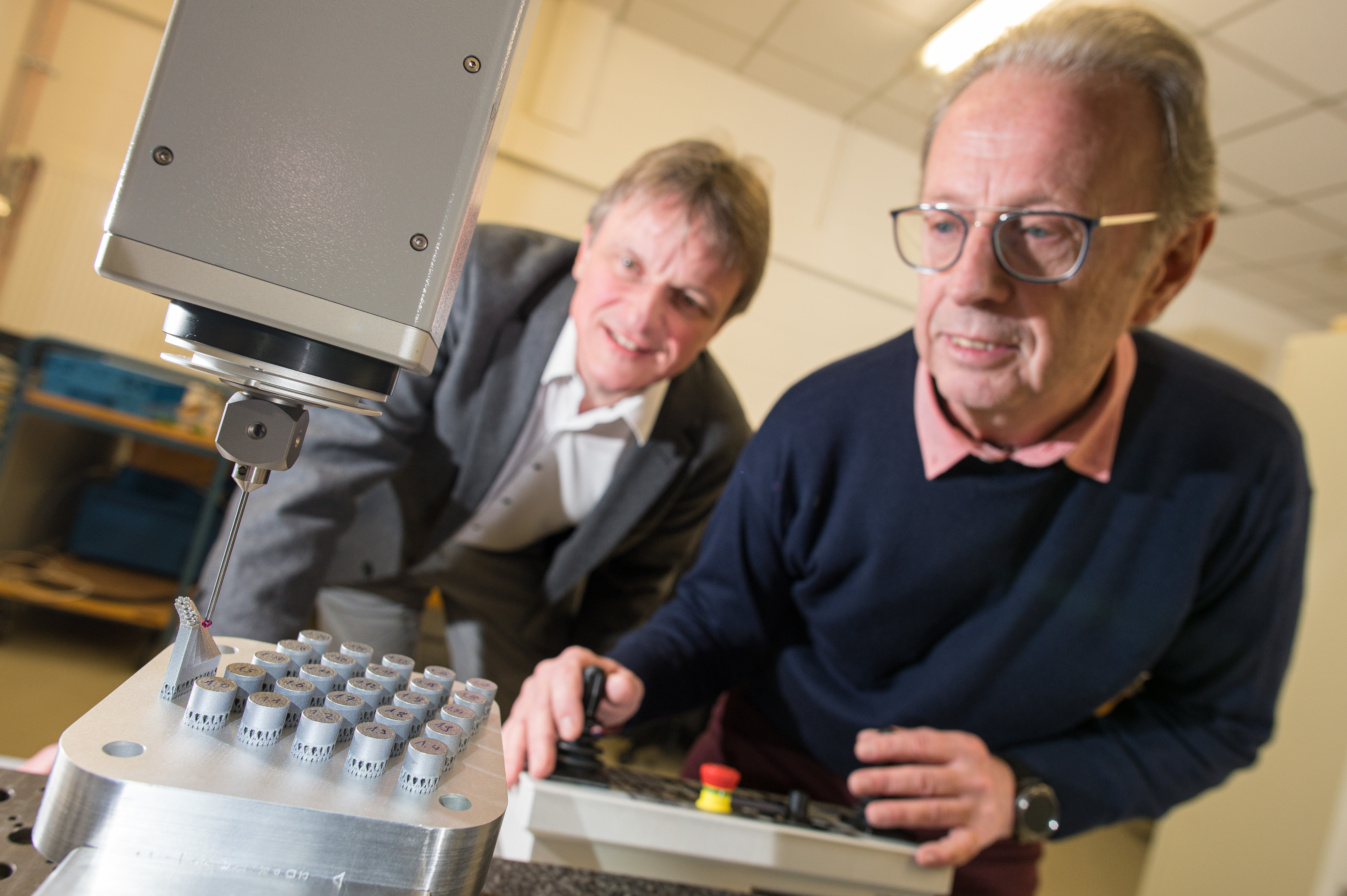

Professor Bähre’s process works by bathing metal 3D printed parts in a flowing electrolyte solution, which can then be electrochemically machined to the required geometry working to tolerances of a few thousandths of a millimetre. This can be done without any mechanical contact and without imparting any mechanical stresses to the workpiece, explain the researchers. To do so, engineers simply require a source of electrical power. A high electric current flows between a tool (the cathode) and the conductive workpiece (the anode), which in this case is a 3D printed metal component. The metal part is then immersed in a conducting fluid (the electrolyte); the electrochemical machining process causes minute particles of metals to be removed from the surface of the workpiece.

The metal atoms on the surface of the workpiece enter the solution as positively charged metal ions, allowing the workpiece to very precisely attain the required geometric form. “By adjusting the duration of the current pulses and the vibration of the tool, we can remove surface material very uniformly leaving particularly smooth surfaces and achieving high dimensional precision,” adds Professor Bähre.

The researchers rigorously examined the different metals used as well as the individual process steps involved, in order to gain a thorough understanding of the method. “By meticulously examining both process technology and material behaviour, we can improve and optimize the electrochemical methods in order to obtain even smoother surfaces or more complex geometries at even higher levels of precision,’ explains Professor Bähre.

The team carried out a number of experiments in which they first 3D printed the metal part and then determined how the subsequent electrochemical machining stage can be optimized to yield the required results. “We examined in detail how the different material and process parameters interact and then determine how the overall production process should be configured,” concludes Professor Bähre.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.