Belgian software and 3D printing service provider Materialise has introduced new features to Materialise Magics 24, as well as next-generation Build Processors designed to drive serial additive manufacturing.

As the latest version of the company’s software, Magics 24 includes Support Transfer, Support Transparency and faster nesting options which reduce the build preparation process for users in order to scale their 3D printing operations.

Fried Vancraen, CEO of Materialise, stated, “Technology advances continue to improve productivity of the 3D printing process and support the integration with existing manufacturing environments.”

“This will help to remove some of the remaining barriers to adoption and stimulate companies to adopt 3D printing not just for its unique design and production benefits but also as part of a connected industrial manufacturing process.”

Materialise Magics 24

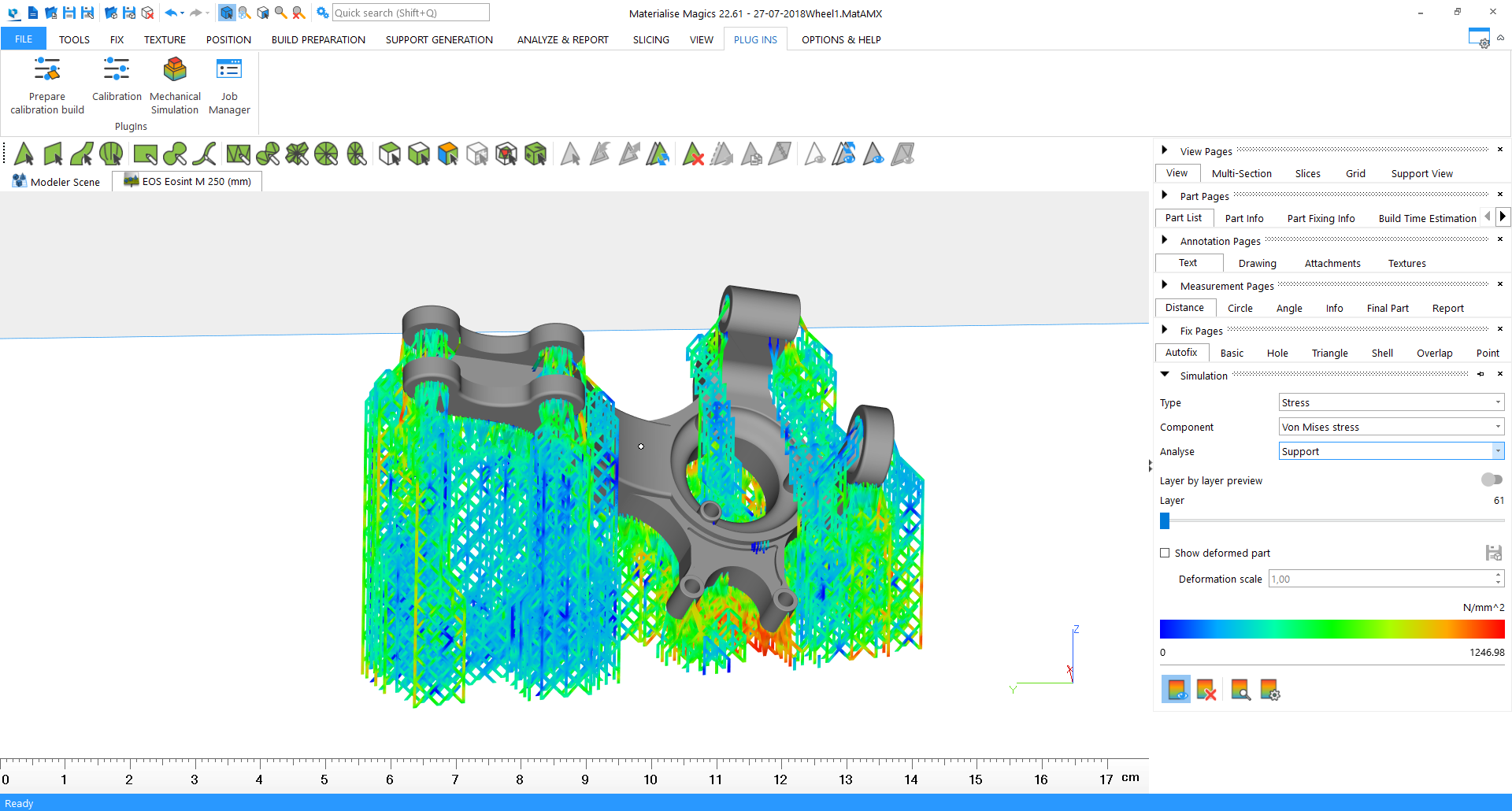

Magics, the flagship software suite of Materialise, provides data and build preparation, as well as STL repair. In Magics 24, the tool has been upgraded to aid manufacturers in the optimization of production processes for scaling operations. One of the new features includes a Bounding Box option which reduces nesting processes to milliseconds, said to be 30 times faster than its predecessor Magics 23.

Furthermore, a new Support Transfer feature allows mass customization by copying the support generation of an object and transferring it to similarly shaped objects. This eliminates the need for complete redesigns od support structures. In addition, a Support Transparency feature enables users to make the support structures transparent, for optimal viewing upon inspection. The ability to schedule multiple simulation sessions is also available to run operations run.

“We continue to introduce new innovations and improvements to increase productivity and efficiency in the 3D printing process,” added Stefaan Motte, Vice President and General Manager of the Materialise software division.

“But as companies scale their 3D printing operations and integrate these operations with existing and proven production processes, they are confronted with increased complexity. By collaborating with other industry leaders, we are able to optimize the entire process and create a more seamless workflow.”

Driving series production

As well as Magics 24, at Formnext 2019 this week Materialise will unveil a vision of its next-generation Build Processors that also advance serial production. Such Build Processors translate 3D designs into machine-specific build files for various additive manufacturing systems.

Materialise aims to create a closer integration between software and machine with future Build Processors which are modular in design, allowing machine builders to integrate their proprietary software. Thus, the company is working with EOS, to develop a Build Processor integrating EOSPRINT software, enabling direct 3D printing on EOS machines. This will be available in the first half of 2020.

The company has also entered into a collaboration with South Korean multi-function printer and 3D printer manufacturer Sindoh to integrate its software as well as develop a new generation of Sindoh 3D printers.

“A seamless data preparation workflow with automation capabilities is one of our top customer requests,” continued Rüdiger Herfrid, Product Line Manager Data Preparation at EOS. “We are pleased that Materialise, as a preferred EOS partner, will use the open interface to offer a consistent data preparation workflow for EOS machines.”

View all of Materialise’s latest solutions at Formnext at Hall 12.1, Booth C131.

Keep up with the latest news from Formnext by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a factory floor powered by Streamics 8. Photo via Materialise.