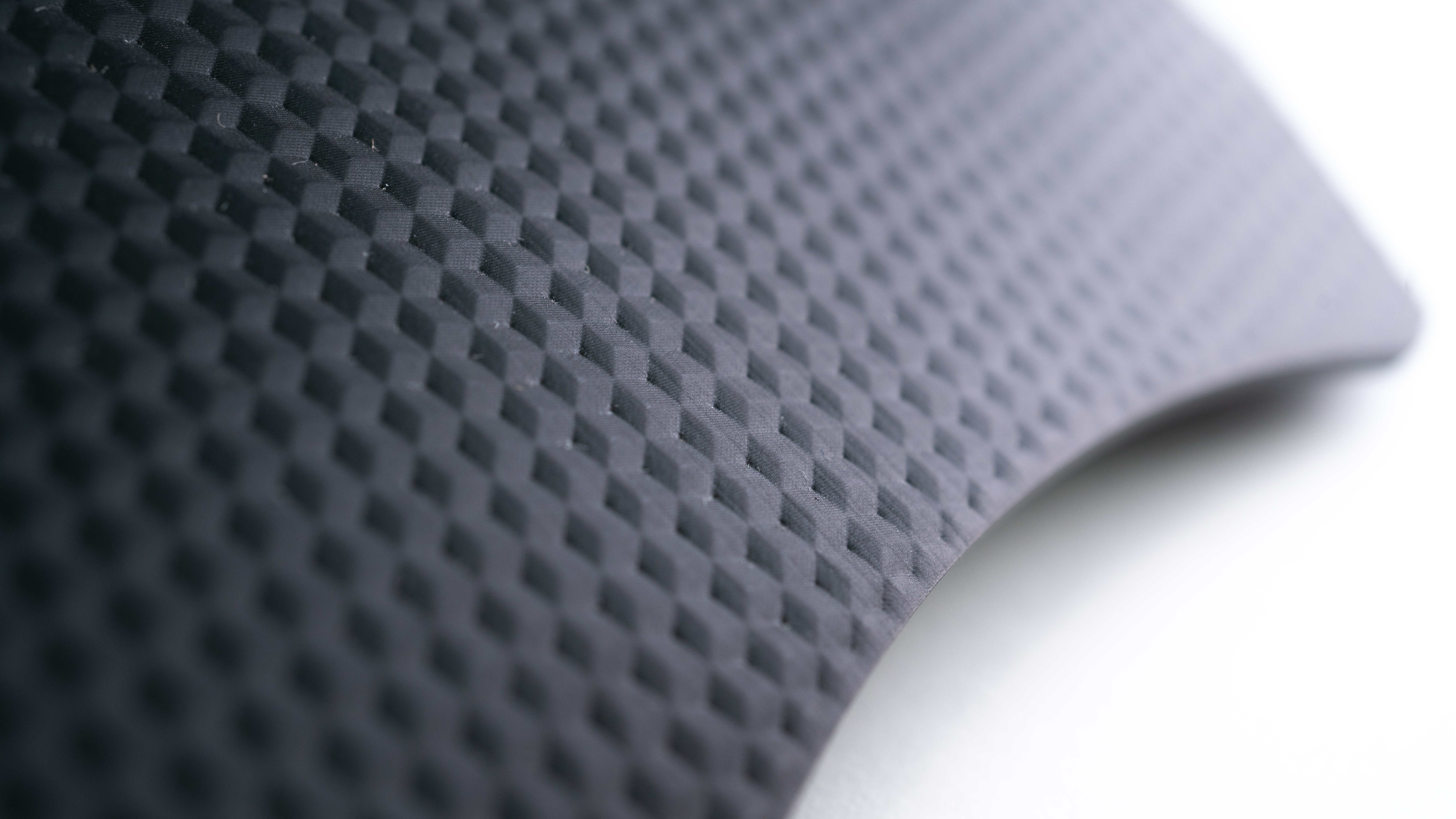

Carbon, the Silicon Valley-based firm behind Digital Light Synthesis (DLS) technology, has introduced a new resin to its portfolio of 3D printing materials, called the RPU 130. Set to debut at the K Trade Fair in Dusseldorf next week, RPU 130 is designed to be a tough, rigid and high-temperature material for the automotive industry, as well as consumer and industrial applications.

Carbon developed the resin with the intention of addressing the demand for an additive material with high impact resistance and dimensional stability at elevated temperatures. Furthermore, 30% of RPU 130 is made of Susterra propanediol, a sustainable plant-based material from DuPont Tate & Lyle, a firm specializing in bio products.

“Our materials team at Carbon is second to none, and RPU 130 represents a true breakthrough in what is possible for new additive materials,” commented Dr. Joseph DeSimone, Co-Founder and CEO of Carbon. “Although some of these properties have been available before in additive, RPU 130 is the first to combine them all into a single manufacturing material suitable for the most demanding conditions.”

“We are really proud of the science that went into bringing this innovative material to market.”

More sustainable 3D printing materials

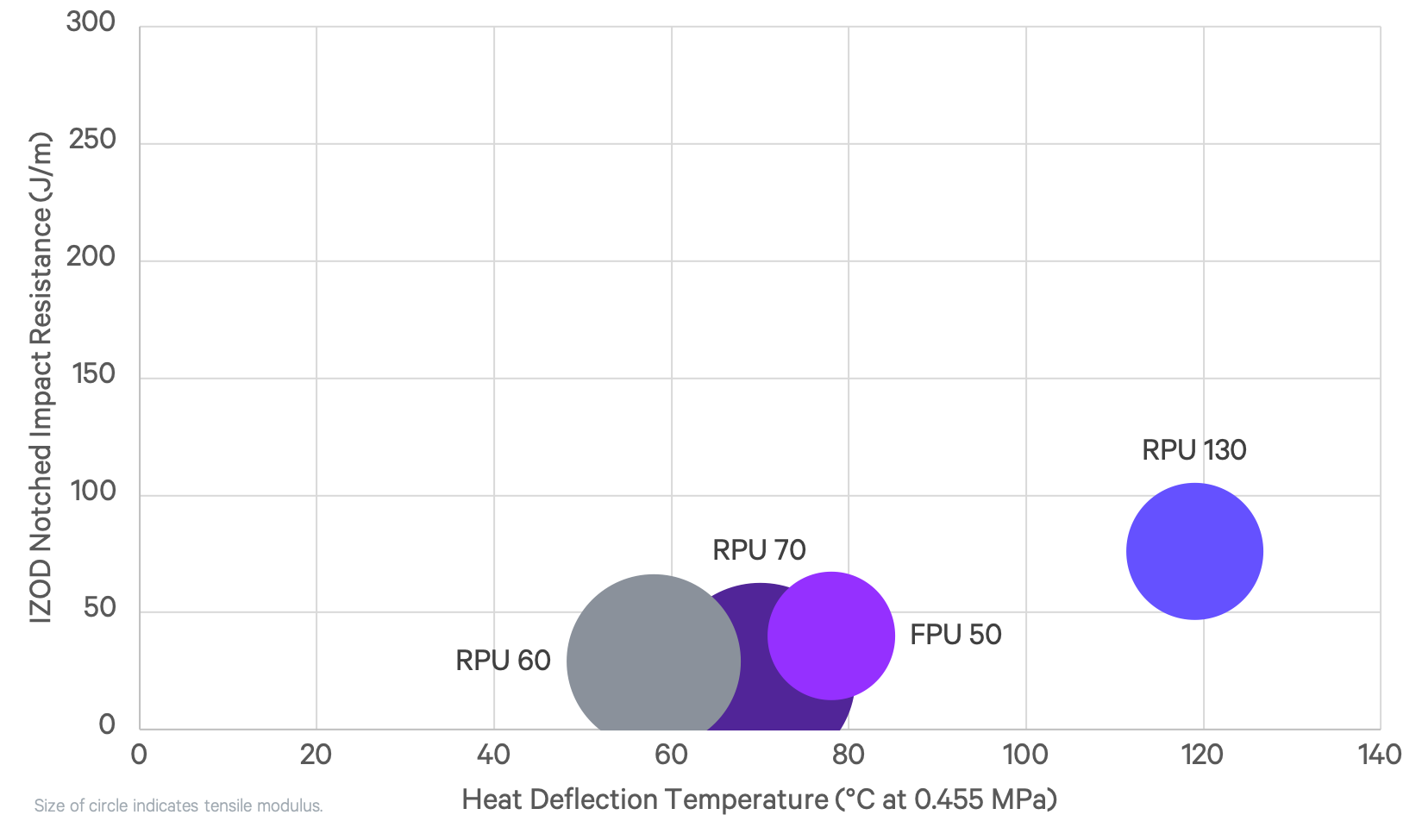

RPU 130 extends Carbon’s rigid polyurethane line of resins, which includes RPU 60, RPU 61, and RPU 70. The rigid materials cover a versatile range of properties between them, now expanded with the addition of the new resin.

Carbon engineered RPU 130 to combine the properties of its RPU 70, FPU 50, and EPX 82 resins, resulting in a tough, heat and impact resistant material, matching the properties of ABS, unfilled nylon, or polypropylene. Its properties make it suitable for a wide range of applications, like air ducts and brake caliper covers for vehicles, sunglasses, tool housings, and device enclosures.

Carbon partnered with DuPont Tate & Lyle in order to create a more sustainable method of developing its materials. DuPont Tate & Lyle is a joint venture between DuPont, a global science company, and Tate & Lyle, a world-leading specialty ingredients and solutions company. The former has a large portfolio of 3D printing materials itself, with extensive experience in developing them with a number of 3D printer manufacturers. The joint venture is focused on providing higher-performing ingredients from a petroleum-free, sustainable, and renewable source.

DuPont Tate & Lyle’s Susterra propanediol product, used to make the RPU 130 resin, is a 100% bio-based building block. It is said to produce 48% less greenhouse gas emissions than conventional petroleum-based alternatives. It also uses 46% less nonrenewable energy through its life cycle. With the use of Susterra propanediol, Carbon has expressed a commitment towards further usage of bio-based materials in its products, in a bid to achieve more sustainable practices.

“We are focused on ways to incorporate more sustainable approaches to developing materials, and our partnership with DuPont Tate & Lyle emphasizes that commitment. We believe that sustainability can go hand-in-hand with improved performance. In the case of RPU 130, we believe it will make the material even more appealing for our customers, as it makes it possible to create better quality products that are also ultimately better for the environment,” explained Jason Rolland, SVP of Materials at Carbon.

The new material is made exclusively for Carbon’s DLS technology, engineered using the firm’s patented continuous liquid interface production (CLIP) dual-curing process. Alongside the resin, Carbon is also offering a separate C5 Cassette add-on for its 3D printers that are required for use with the material, as well as a new dispensing solution and software for tuning the material for printing. RPU 130 is available for purchase in the USA, Canada, and Europe. To learn more about the material, you can visit Carbon’s booth at K-Show from October 16-23 located at H7.2, F12.

Developing Carbon DLS materials

Recently, Carbon’s DLS technology and materials have been available through a number of manufacturing services and platforms, in a bid to make its technology more accessible to customers. It was recently added to Protolabs’ portfolio of production-grade additive manufacturing technologies, with the aim of empowering Protolabs customers to move into the production of functional and detailed parts.

Carbon’s materials were also made available through the Shapeways 3D printing service bureau this year, and on the Xometry on-demand manufacturing marketplace. Furthermore, the company has also partnered with Covestro, a German manufacturer of high-performance polymers, to enable mass production of Carbon’s polyurethane liquid resin. The partnership followed news of a $20 million investment from Arkema to the Carbon Growth Funding Round in June, in order to develop a new era of materials performance as well as an innovative supply chain model.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows key fob made with RPU 130 resin. Photo via Carbon.