BASF 3D Printing Solutions (B3DPS), a subsidiary of German chemical company BASF, has debuted a new range of photopolymer and laser sintering materials as well as several strategic partnerships at Formnext.

Such partnerships include Origin, a silicon valley additive manufacturing startup, Photocentric, a UK-based manufacturer of photopolymers, and Xunshi Technology, a Chinese 3D printer manufacturer.

BASF’s material partnerships

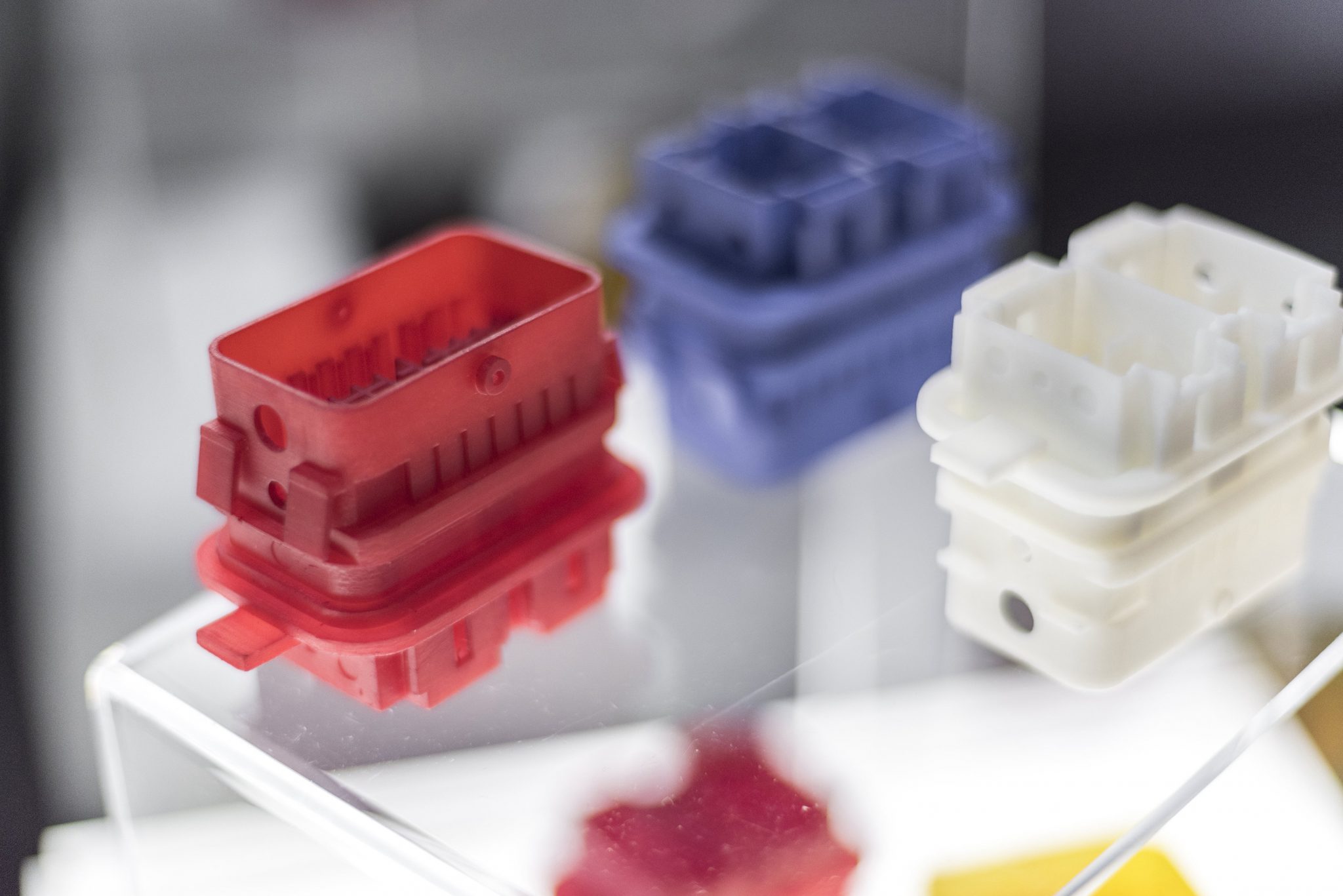

Earlier this month, Origin secured $10 million in series A funding as well as a materials development partnership with BASF. This collaboration has led to a new printing process for BASF’s Ultracur3D photopolymers, offering improved surface finishes, high mechanical stability, and high material throughput.

“Within the framework of an open business model, we are combining BASF’s material know-how with Origin’s expertise in printer software programming and the manufacture of the corresponding hardware,” explained Volker Hammes, Managing Director, B3DPS.

B3DPS is also partnering with together with Photocentric, the manufacturer of the largest LCD 3D printer – the Liquid Crystal (LC) Maximus – to develop new photopolymers and large-format photopolymer printers for mass production. Moreover, B3DPS and Xunshi Technology, which operates in the U.S. under the name Sprintray, will collaborate to identify new fields of application in 3D printing for the Ultracur3D product range.

Ultracur3D and new materials from B3DPS

The new range of photopolymers for additive manufacturing from B3DPS integrates “unique raw materials” for special part properties. “Our Ultracur3D portfolio enables us to offer customers various UV-curable materials for 3D printing that provide far better mechanical properties and higher long-term stability than most available materials,” stated András Marton, Senior Business Development Manager at B3DPS.

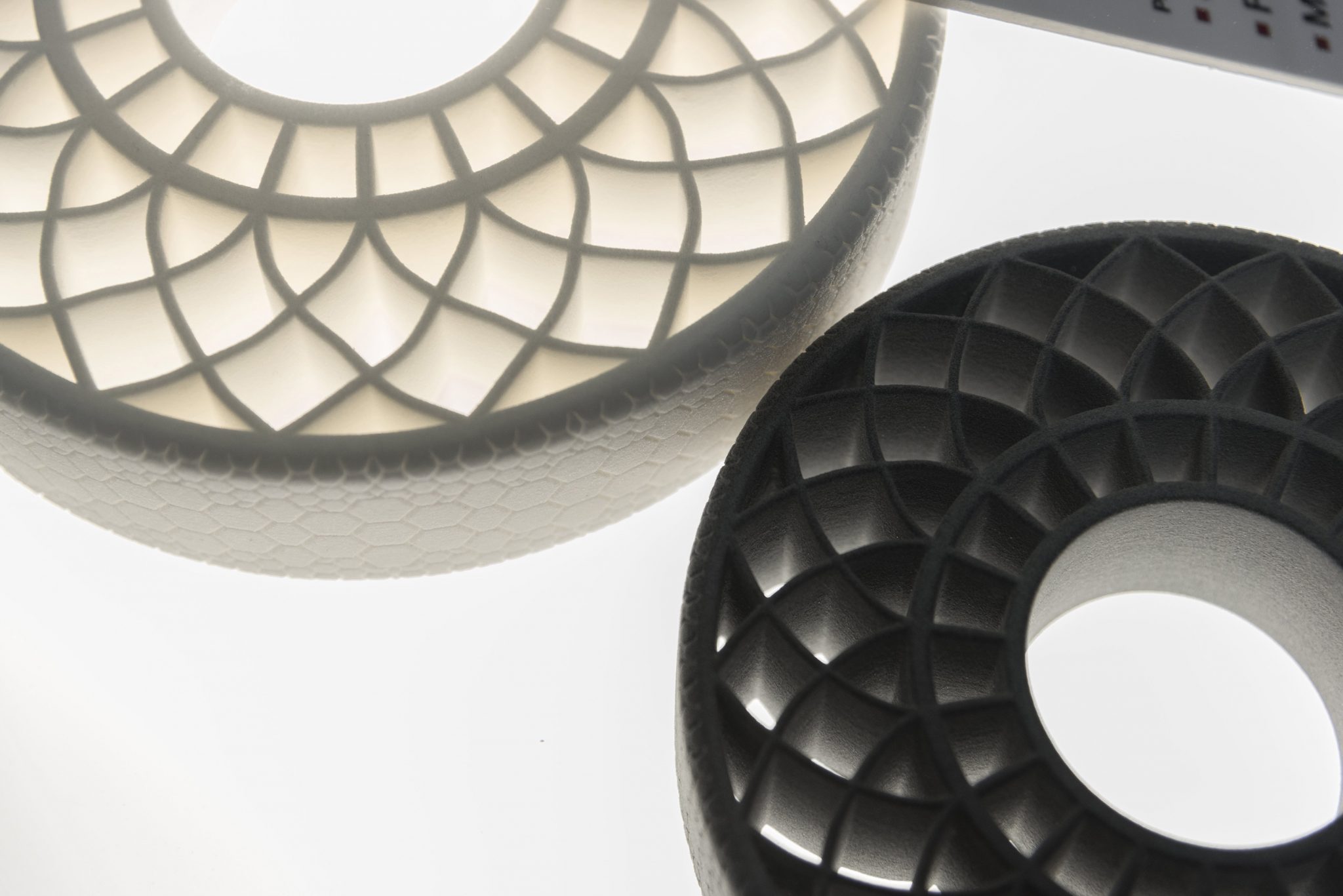

Furthermore, as a result of B3DPS’ acquisition of Advanc3D Materials, B3DPS has expanded its range of Selective Laser Sintering (SLS) materials with the flame-resistant Ultrasint Polyamide PA6 Black FR, Ultrasint PA6 Black LM X085, polyamide Adsint PA12, Adsint PA11, Adsint PA11CF and Adsint TPU flex 90.

A distribution network expansion for BASF filaments

In addition, B3DPS’ subsidiary Innofil3D, is entering into a partnership with Jet-Mate Technology, a Tjanjin-based chemical company, for the distribution of plastic 3D printing filaments in China. An agreement has also been confirmed with M. Holland, an international distributor of thermoplastic resins, for the distribution of filaments in USA.

“Since the USA is the largest market for filaments, we intend to strengthen our activities there. Asia is another important market for us. We will be developing further distribution channels there and putting our Ultrafuse filaments on the Asian market in 2019,” said Jeroen Wiggers, Business Director 3DP Solutions for Additive Extrusion at B3DPS.

The latest 3D printing materials from B3DPS can be found at Formnext, Stand F20 in Hall 3.1.

For more news on 3D printing and the latest releases from Formnext, subscribe to our 3D printing newsletter. You can also follow us on Twitter and Facebook.

Visit our 3D Printing Jobs to start a new career in 3D printing.

Featured image shows BASF Ultrafuse 316LX sintered parts with internal honeycomb infill. Photo via BASF.