3D Printhuset, a Danish 3D printing reseller, service provider and developer, has reportedly won the “first EU tender ever for a construction 3D printer” with Kamp C in Belgium.

The sustainability and innovation driver for construction in Antwerp Province, Kamp C has acquired Printhuset’s BOD2 3D printer and plans to use the machine in its development of a 3D printing infrastructure for the city of Flanders.

“We are extremely proud and pleased that Kamp C chose us in competition with the many other contenders that always appear in such EU tenders,” comments Henrik Lund-Nielsen, CEO of 3D Printhuset.

“The BOD2 is the only second generation printer on the market and is really unique in the sense that it has been cured [of all the problems of] a first generation printer. Kamp C appreciated this fact and evaluated that we by far not only had the best price but also had the best technical offer.”

The first 3D printed building

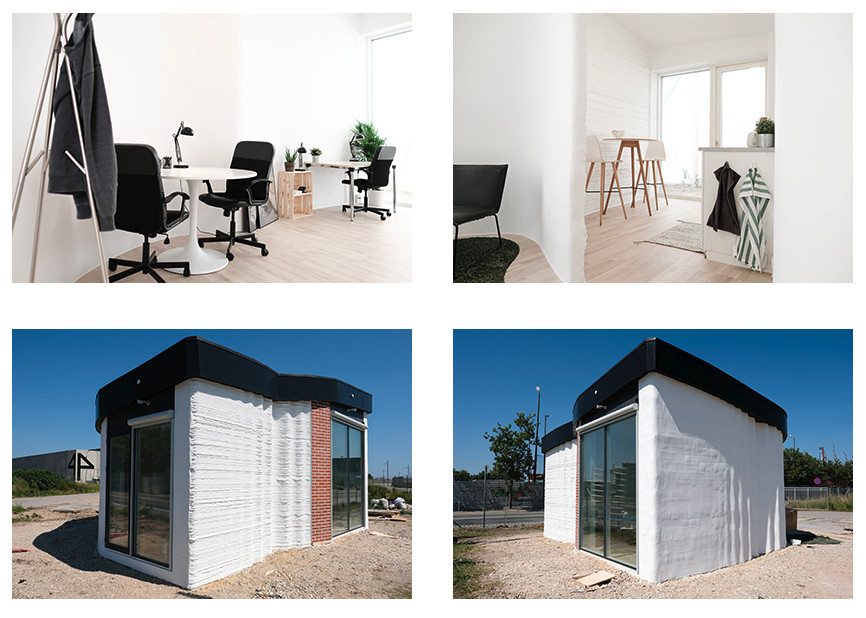

3D Printhuset began 3D printing its first ever public construction project, The BOD office-hotel, in September 2017. Now complete, the BOD stands on site in Nordhavn harbor, Copenhagen. Though technically a habitable shelter, the small BOD office has really served as a proofing ground for 3D Printhuset’s technology and lessons learned from the process have been used to develop its second generation 3D printer.

Initially limited to 3D printed sizes up to 8 x 8 x 6 meters (X x Y x Z), the original BOD has been upgraded to a modular design relying on the connection between mutiple 2.5 meter long units.

Michael Holm, Development Manager of 3D Printhuset comments, “Following our own BOD project we received many requests for the delivery of multiple sizes of printers,”

“We also knew how to improve this second version, as we learned great many things from doing The BOD with our first printer.”

Bigger, faster, construction 3D printing

The BOD2 construction 3D printer acquired by Kamp C is a version 444, which is capable of printing and area of 9.5 x 9.5 x 8.5 meters (X x Y x Z) meters in the length and width and 8,3 meters in the height.

In addition, the 3D Printhuset team asserts that the BOD2 is “10 x faster than the first generation” achieving print speeds of up up to 1000 mm/s, or 1 meter per second. The previous version reported top speeds of up to 2.5 m/m, with an average layer height between 50 and 70 mm.

3D printing in construction

Arguably one of the most popular and accessible applications of 3D printing, construction has gathered a lot of interest with companies launched for the purpose all over the world.

In Russia, Apis Cor shared reports of a house 3D printed in just 24 hours. At Massachusetts Institute of Technology (MIT), Neri Oxman’s Mediated Matter team have developed a robot that can 3D print a structure in just 14. And, most recently, the Ramdani family became the first people to move into a 3D printed house produced by the University of Nantes (IUT) Yhnova project.

To stay up to date with 3D printing construction projects follow 3D Printing Industry on Twitter, like us on Facebook, and subscribe to our newsletter. For 3D Printing Jobs, sign up here.

Featured image shows The BOD by 3D Printhuset. Clip via 3D Printhuset