Researchers at the University of Illinois Urbana-Champaign have developed a hypnotizing 3D printer that offers new possibilities in the field of tissue engineering.

Seemingly gravity-defying, the 3D printer makes objects suitable for seeding cells and growing tissue samples in-lab, a crucial step when experimenting with potentially ground-breaking treatments.

Tissue engineering: the challenges

In medical research, 3D printing acts as an upgrade to the typical petri-dish sample. Instead of a single, 2D layer of cells, 3D printed scaffolds are enabling the creation of complex cell-structures that more accurately represent the human body.

Using 3D printed scaffolds, researchers have been able to create lung, kidney and bone tissue samples.

Though the scope of the application is virtually limitless, one challenge remains the same – once we have grown cells on these scaffolds, how do we remove the unwanted material? The University of Illinois’ research presents a novel answer to this question.

3D printing carbohydrate glass

Isomalt, the sweet ingredient of sugar-free candies, is used as the primary material of Illinois’ newly developed 3D printer. Like its prolific alternative, isomalt is soluble, and digestible, making it easy to remove when it is no longer needed.

In broader terms, the material known as a “carbohydrate glass,” relating to its optical quality, and rapid solidification at room temperature. In other research, carbohydrate glass has been used to create artificial blood vessels, and in therapeutic patches.

A tuneable process

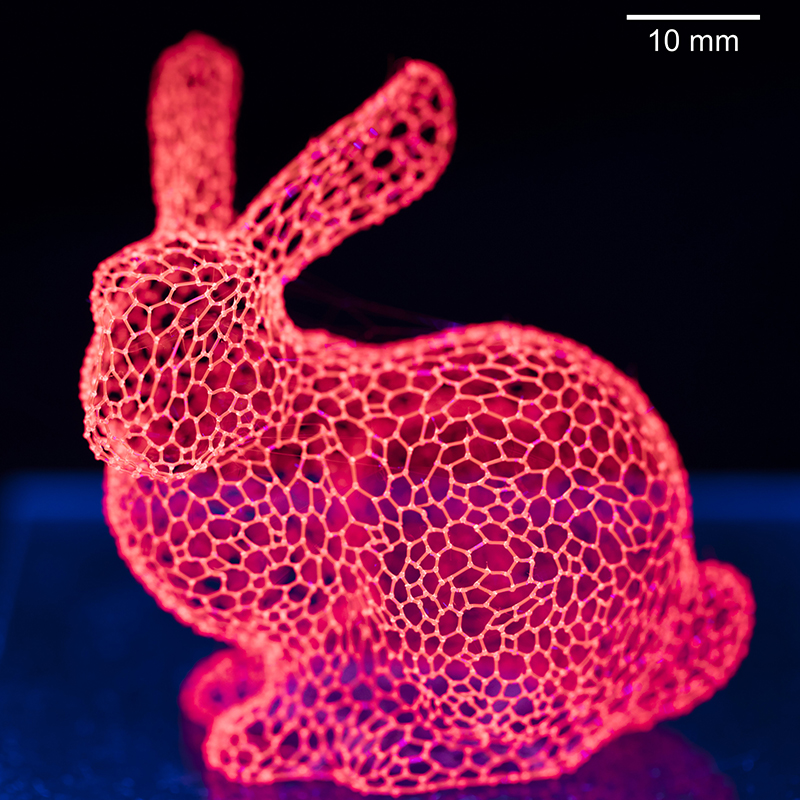

One of the significant breakthrough’s of the Illinois isomalt 3D printer, is that its objects can have varied structures.

A truly free-form approach, 3D printing materials like carbohydrate glass offers geometries that would be impossible in a layer-by-layer methods.

Giving the Stamford Bunny as an example Rohit Bhargava, professor of bioengineering at Illinois and co-author of the study detailing the isomalt 3D printer, explains, “We could, in principle, change the mechanical properties of the tail of the bunny to be different from the back of the bunny, and yet be different from the ears,”

“This is very important biologically. In layer-by-layer printing, you have the same material and you’re depositing the same amount, so it’s very difficult to adjust the mechanical properties.”

Cancer research, drug development and medtech

As director of the Cancer Center at the University of Illinois Urbana-Champaign, Bhargava sees the potential for the isomalt 3D printer to be used to make replica tumors for study in lab. Other potential applications are in the area of drug development, and making medical devices.

The professor concludes, “This printer is an example of engineering that has long-term implications for biological research,”

“This is fundamental engineering coming together with materials science and computer science to make a useful device for biomedical applications.”

“Model-guided design and characterization of a high-precision 3D printing process for carbohydrate glass” is published in the latest edition of Additive Manufacturing journal. The study is co-authored by M.K.Gelber, G.Hurst, T.J.Comia, and R.Bhargava.

For more cutting-edge 3D printing powered research, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for all the latest stories.

Sign up to 3D Printing Jobs and seek new opportunities in your field.

Featured image shows spring 3D printed using the Illinois isomalt 3D printer. Image by Matthew Gelber/University of Illinois Urbana-Champaign