Studying the behaviour of a single layer of cells, scientists realized that the two-dimensional approach was not enough. To this, they added a third dimension and 3D printed scaffolds for cells to proliferate in a way more faithful to the human body. Now, in an effort to match the minute scale of human blood vessels, Professor Leonid Ionov and his team at the University of Bayreuth, Germany, and previously the University of Georgia, have decided that 4D bioprinting is the way forward.

Clip demonstrating living, beating heart cells inside a self-rolled polymer tube. Video via Leonid Ionov on YouTube

It’s morphing time!

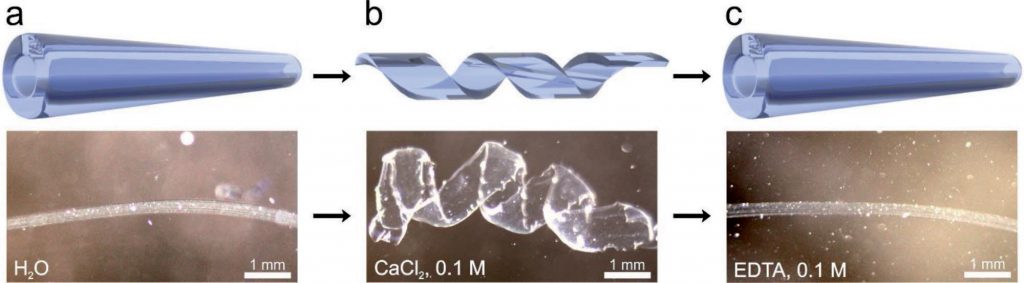

As in 4D printing, items made by 4D bioprinting are first deposited as a flat shape. With the addition of water and heat, this net then folds itself into a new 3D shape pre-programmed by researches into the material’s makeup. By employing this ability to self-actuate, Ionov Lab researchers bypass resolution limitations of other 3D bioprinters.

At this stage of the technology’s development, typical 3D bioprinters are capable of making tubes at a scale of tens to hundreds of microns in diameter. By comparison, the diameter of the smallest blood vessels in the human body is around 5 microns. Achieving fabrication of a structure so small is a significant challenge to the technology, and key to the ability to create complex tissue for therapeutic treatments, and more accurate drug tests.

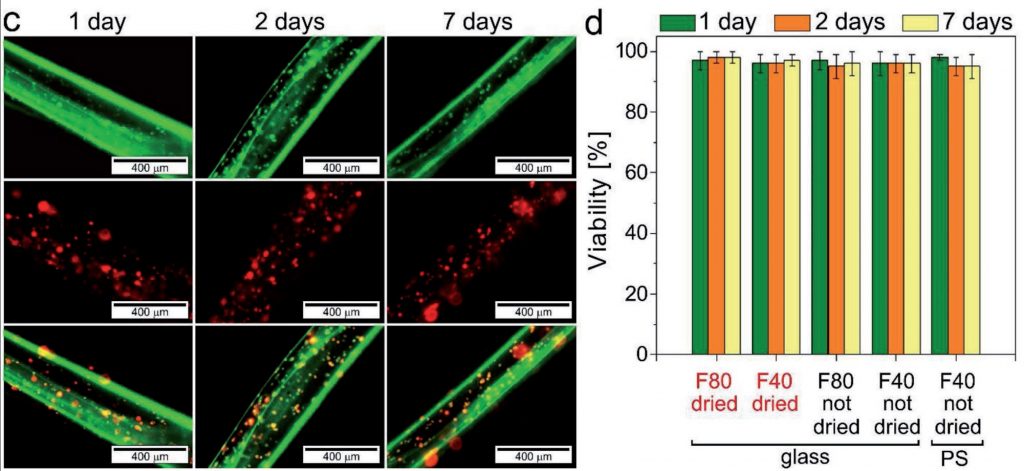

Cells survive for 7 days

4D bioprinted vessels from the Ionov Lab essentially double the resolution of a typical by allowing diameter to be created in the act of self-folding. So far, the method is capable of creating vessels with an average internal diameter of 20 microns a scale “not yet achievable by other existing bioprinting/biofabrication approaches.”

Additionally, the material used (made from alginate and hyaluronic acid) “does not pose any negative effect on the viability of the printed cells” supporting the survival of mouse bone marrow for up to 7 days.

According to the study’s conclusion “the presented approach paves new avenues for the creation of tailored cell-laden shape-morphing architectures for tissue engineering and regenerative medicine applications.”

Further reading

The Ionov Lab’s latest 4D bioprinting vessel research is published online in Advanced Materials as “4D Biofabrication Using Shape-Morphing Hydrogels”. The paper is co-authored by Alina Kirillova, Ridge Maxson, Georgi Stoychev, Cheryl T. Gomillion and Leonid Ionov.

3D printing research is digested daily in the 3D Printing Industry newsletter, on Twitter and Facebook. Register on our 3D printing jobs site here.

Featured image shows jars containing samples of mass-produced 4D bioprinted vessels. Photos via Advance Materials, Supporting Information