Seoul’s Rural Development Administration (RDA) and Hallym University have collaborated to create a 3D Silk-Printing System that produces components suitable for use in vivo, i.e. within a living organism.

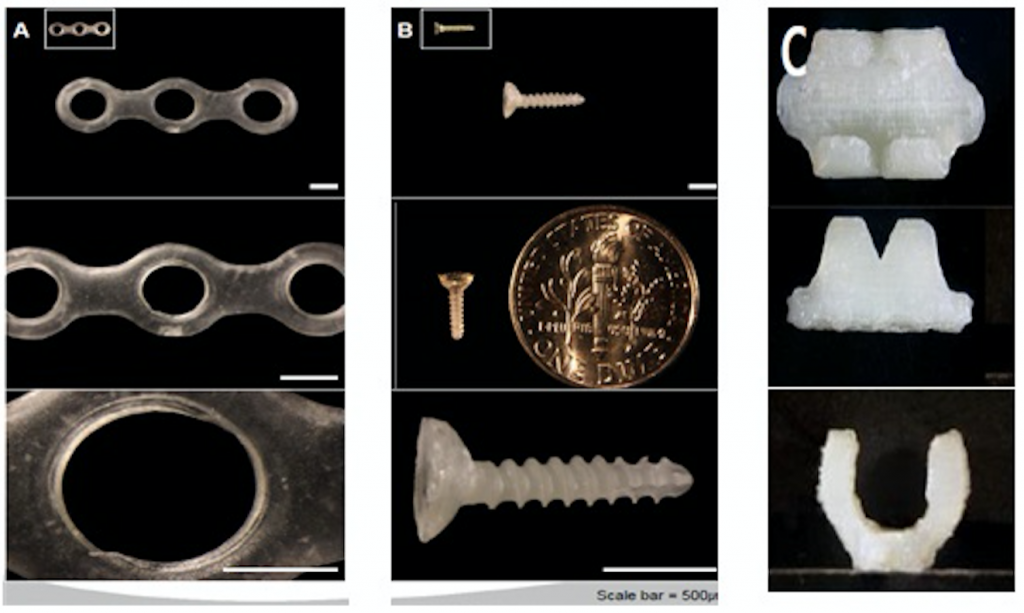

The silk ‘filament’ is made from the fibroin protein that also constitutes 75% of the silk naturally produced by spiders and larvae of members of the moth family. Fibroin is also used in the production of medical-grade objects due to its biocompatibility, and has been the subject of a recent study exploring its potential as preservative in food. What the RDA and Hallym have managed to do with fibroin is recreate the plates and screws used to pin broken bones. An RDA official explains;

“Once the technology becomes commercialized, it will allow for the production of a greater variety of biocompatible silk medical equipment, which will help improve national health while developing Korea’s sericulture (silk production) industry.”

Traditional metal implants can cause a lot of inconvenience for the people who use them – they can and have led to undue harassment when passing through airport security, and may have to be surgically removed from the body at some point in the future. As we have previously reported on 3DPI, there are also other plastic polymer substitutes aiming to solve the same biomedical problems. For example, the hyperelastic bones developed by Northwestern University could be one potential solution.

These bones are created from calcium and plastic composite material, tests show the sample perform well under compressive strain and, like this printed silk, are degradable. However, Northwestern’s calcium composite material has not yet been demonstrated in the same way as this silk, and so its potential use as a surgical plate or screw remains, at this stage, speculation. Usually plastic polymers aren’t strong enough for implementation in fracture surgery, the ‘silk ink’ described by this research points towards a strong, durable and, relatively low cost option.

Featured image: Silk cocoons in Dalat, Vietnam Photo via: yoyo_hick on flickr